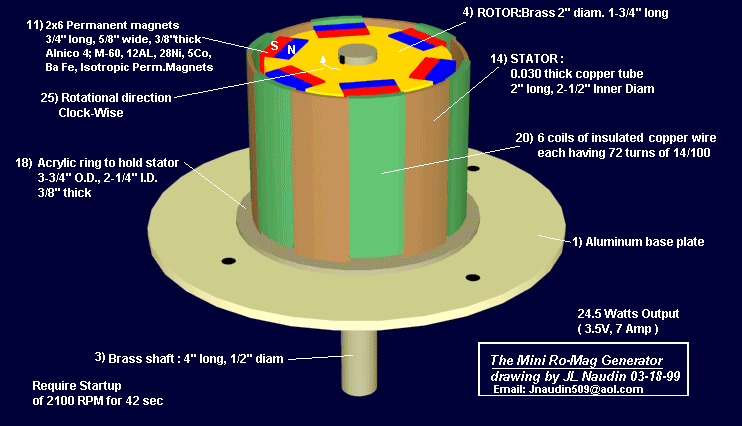

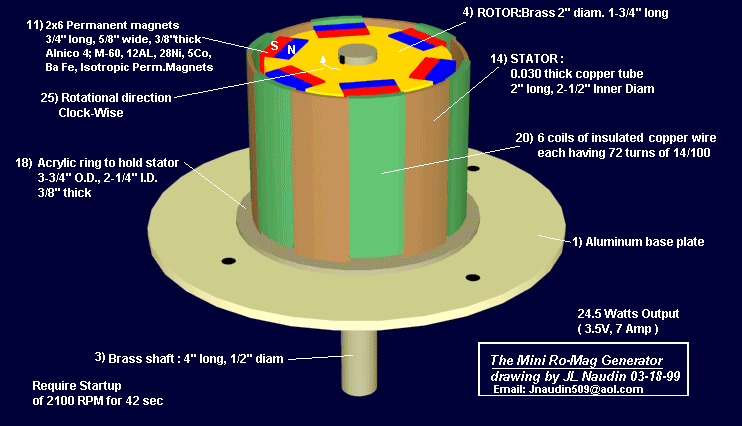

The Mini Romag free energy generator

from Magnetic Energy uses the principle of moving magnetic flow named

“the magnetic current” for generating electrical power. According to

Magnetic Energy this generator is able to produce 3.5 volts, 7A DC (

about 24 Watts ) of free electricity while its generate sufficient power

to sustain itself…

The Mini Romag free energy generator

from Magnetic Energy uses the principle of moving magnetic flow named

“the magnetic current” for generating electrical power. According to

Magnetic Energy this generator is able to produce 3.5 volts, 7A DC (

about 24 Watts ) of free electricity while its generate sufficient power

to sustain itself…

This

generator need to be started by an external motor during about 42

seconds at 2100 RPM. After this charging process, when the energy flow

is established in the Romag generator, the motor can be removed and free

electrical energy can be used.

The Romag

free energy generator

is a new revolutionary concept which generates electrical energy

without using the first flow of current generated by magnetism, it uses

only the untapped natural resource of the magnetism…

HOW THE UNIT WORKS :

The

here disclosed 3½ volt, 7 amperage magnet motor/generator must be

charged up by driving the main shaft at 2100 RPM for 42 seconds. This

charging process manifests as magnetic energy within the six coils of

copper wire, the copper tube supporting these coils and the copper

coated steel wires wrapped around the magnets. This charging is

accomplished while the six coil connection wires, Part #22, are making

contact and setting up their alternating magnetic poles. After the 42

second charging time one of these coil connection wires must be opened

and this circuit again completed through an energy draw at what could be

called 7 amps. See load Part #23. As current is drawn from the six

coils, this draw sets up magnetic poles which are a response between the

rotor magnets and the coils. This response then causes the main shaft

to be rotated by the 12 permanent magnets as they attract and build a

release field. Then the driver unit (hand crank) is disconnected

allowing the unit to rotate with the load being the activating driving

force.

The fields of the magnets must be maintained during their

spin movement. These magnetic fields which are encapsulated are achieved

by the wiring system. The attract/release of the magnets is a function

of several factors. First, the magnets attract field between north and

south is completed by taking a crossing path of attract (top of one row

to bottom of next, etc.). This action has the effect of fields blending

into fields, and a hold-back attract does not happen. Each time a magnet

set passes a coil an interchange of like energy between the coils

around the magnets and the generating coils sets-up neutral polarities

which are ‘release fields’ and prevents a hold-back attract.

One

important magnetic assembly is the circuitry which allows this

interchange of free energy. This is a recycling of a stabilized

magnetic/electro energy not electro/magnetic because the field of force

is not a case of electrical input, an input that created the magnetic

energy, but rather a build-up of magnetic energy which caused a free

energy thrust.

In further defining the workings of this unit it is

important to understand that although electrical and magnetic (energy)

work with similar attitudes, the manner in which they work sets-up a

differing energy effect. One of these effects is that magnetic

structures want to share their f1ow, compatible to the Universal Force,

while electrical flow argues, (short circuits, sparks, etc.). Because of

this fact the working responses (within the unit) take place, how they

are needed, and when they are needed which results in a functioning

unit. There is a continuous transmutation process taking place whereby

magnetic energy continually generates an energy that manifests a

measurable current.

FREE ENERGY GENERATOR

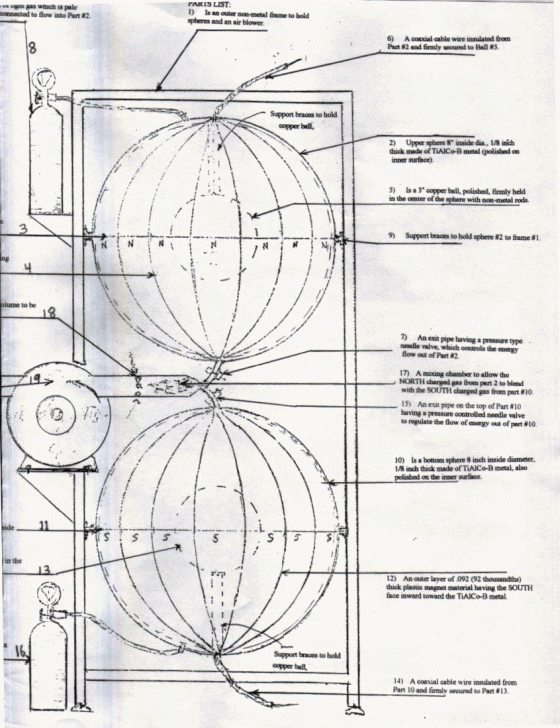

FREE ENERGY GENERATOR PARTS LIST AND CONSTRUCTION DETAILS

When building your first unit we suggest using the stated materials.

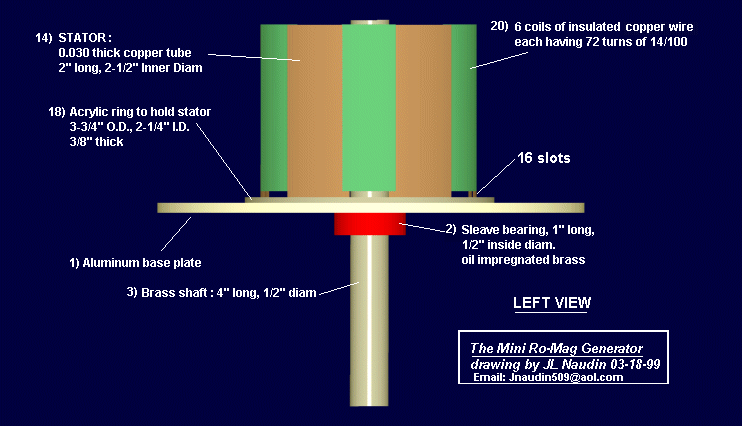

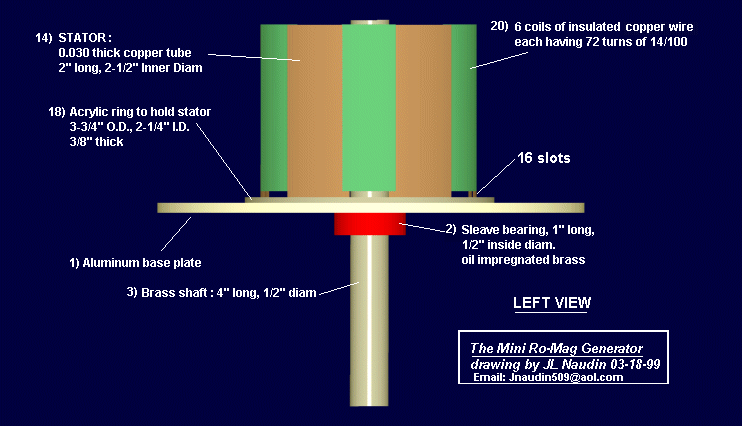

1) Aluminum Base Plate

2) Sleave Bearing, 1″ long, ½” inside diameter, oil impregnated brass.

3) 4″ long by ½” diameter Brass Shaft

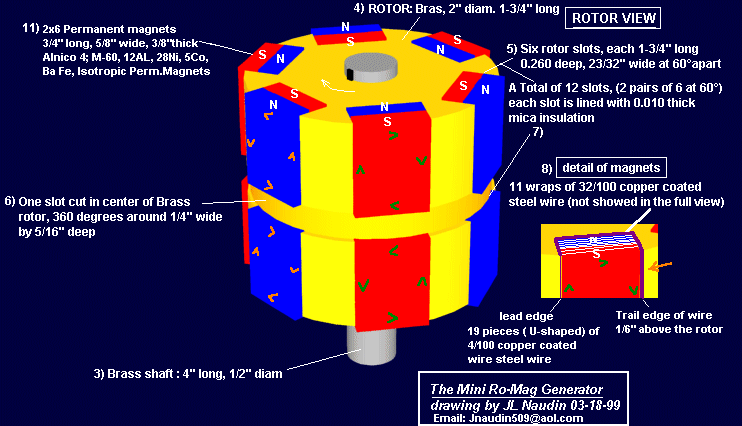

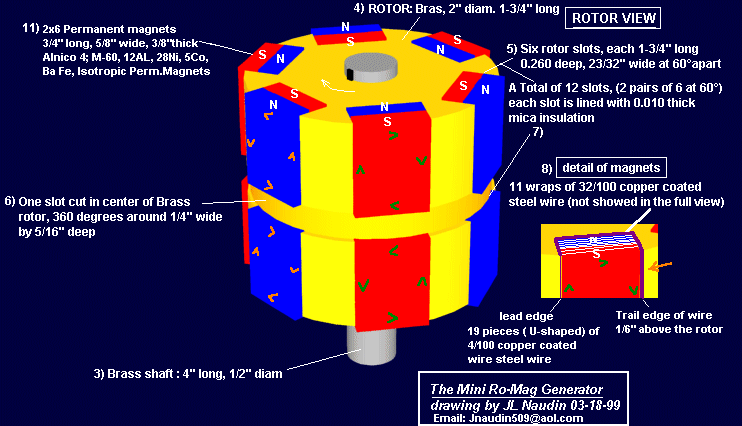

4) Brass 2″ diameter Rotor, 1-3/4″ long

5) Six rotor slots, each 1-3/4″ long by .260 deep by 23/32″ wide. These slots are spaced exactly 60 degrees apart.

6) One slot cut in center of Brass Rotor, 360 degrees around, ¼” wide by 5/16″ deep.

7) 12 slots (formed from the six slots as the 360 degree cut is made). Each slot is lined with .010 thick mica insulation.

8)

A total of 228 pieces of U-shaped .040 thick copper coated steel wires.

Each slot (Part #7) has 19 pieces of these wires fitted into the Mica,

thus these wires do not contact the Brass rotor. The lead edge of these

wires is flush with the Rotor’s outer surface and the trail edge

protrudes 1/8″ above the Rotor’s outer diameter.

9) Eleven

complete turns of .032 thick copper coated steel wire. These 11 turns or

‘wraps’ accumulate to 3/8″ wide and the same pattern is placed around

all 12 magnets. When placed into the bent wires #8, they are a snug fit

making firm contact.

10) Are 12 pieces of .005″ thick mylar insulation inserted into the cores of the wires #9.

11)

12 permanent magnets, insulated with the mylar, to not contact wires #

9. These magnets measure 3/4″ long, 5/8″ wide, 3/8″ thick and are made

of a special composition and strength. Alnico 4, M-60; 12 AL, 28 Ni, 5

Co, bal Fe, Isotropic permanent magnet material cooled in magnetic

field, Cast 9100 TS. 450 Brin, 2.2 Peak energy product. When inserted in

the rotor the outer faces of these 12 magnets are not to be machined to

a radius. The center of these magnets pass the center of the coils with

3/32″ clearance. The edges, where the wires are wrapped, pass 1/32″

away from the coils. This ‘changing magnet spacing’ aids in not only the

release cycle but also contributes to rotational movement. (Sharp

magnet edges which are facing the coils are to be sanded to a small

smooth radius.)

12) Magnet polarity placement into Rotor.

13)

Connection pattern for wires wrapped around magnets. The 12 wire wraps

are divided into two sections, upper and lower of six each. There are no

connections between these sections. The magnetic flow direction between

the upper 6 wraps and the lower 6 wraps is attained by the ‘flow

direction’ as shown in Figure 5. Viewing Figure 6 shows the wires

wrapped around the magnet starting at the top ‘north’ half and then

after 11 complete turns the wire exits at the lower ‘south’ half. As

this wire then goes to the next magnet it arrives at an attract wire

which is its ‘north’ side. Thus all wires get interconnected from south

to north magnet half or north to south magnet half. The actual

connections should be crimped copper clips not solder with insulation

tubing to prevent contact to the Rotor body.

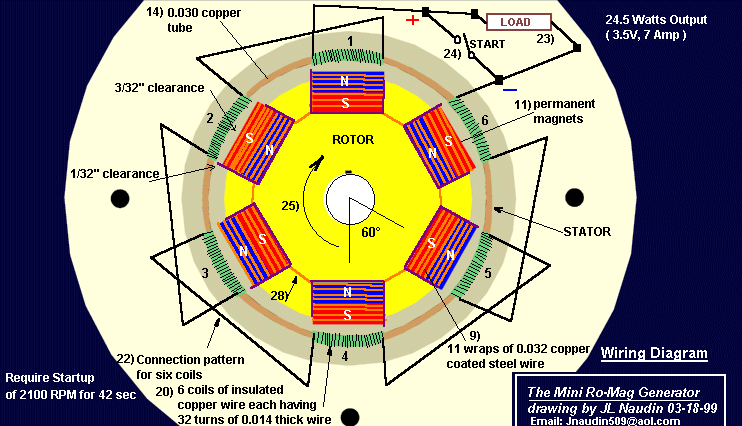

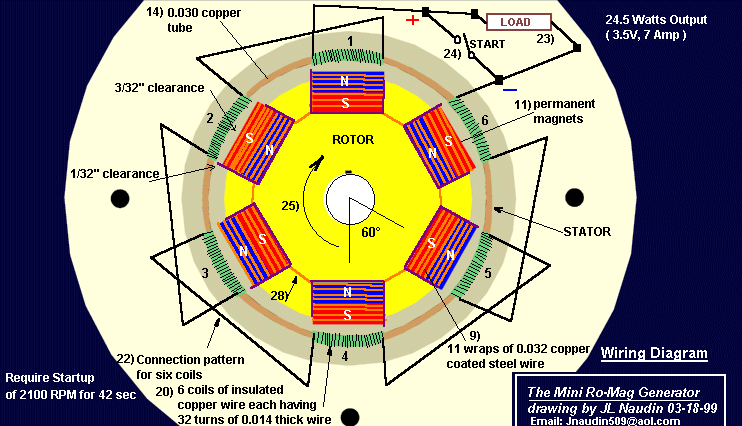

14) A .030 thick copper tube (stiff material) 2″ long by 2½” inside diameter.

15) Are six slots cut at the top of tube #14. These slots are 5/8″ wide by 1/32″ deep spaced at 60 degrees apart.

16) Are six slots cut at the bottom of tube #14. These slots are 5/8″ wide by 5/16″ deep and in line with the upper slots #15.

17) Six copper tube mounting points.

18)

Acrylic ring to hold Part #14, measuring 3-3/4″ O.D., 2¼” I.D., 3/8″

thick bolted directly to Part #1. This ring has a .030 wide groove cut

¼”deep to allow the six copper tube mounting points, Part #17, to be

inserted.

19) A .002″ thick plastic insulation paper to be placed around the inside and outside of Part #14.

20)

Are six coils of insulated copper wire, each coil having 72 turns of

.014 thick wire. Each coil is wound with two layers, the bottom layer to

completely fill the 5/8″ wide slot with 45 turns and the top layer to

span 5/16″ wide with 27 turns. To be sure each coil has the exact wire

length or 72 turns, a sample length wire is wrapped then unwound to

serve as a template for six lengths. A suggested coil winding method is

to fill a small spool with one length then by holding the copper tube at

the lower extension, then start at the plus wire in Figure 2 and

temporarily secure this wire to the outer surface of the tube. Next,

place the pre-measured spool of wire inside the tube, wrapping down and

around the outside advancing clockwise until the 5/8″ slot is filled

with 45 turns. Then, return this wire back across the top of the coil

for 15/32″ and winding in the same direction again advance clock-wise

placing the second layer spanned for 5/16″ with 27 turns. This method

should have the second layer perfectly centered above the first layer.

After winding this coil, repeat the process by again filling the small

spool with another length of pre-measured wire. A very important

magnetic response happens as all six coils have their second layers

spaced as disclosed.

21) This number identifies the top view of the second layer.

22)

Connection pattern for six coils. When the unit is driven at start-up

(hand crank) for 42 seconds at 2100 RPM, all six jumper wires must be

together which means the plus wire goes to the minus wire connected by

the start switch. After 42 seconds the load is added to the circuit and

the start switch is opened. To double check your connections between the

coils, note that the finish wire of coil #1 goes to the finish wire of

coil #2, which is top layer to top layer. This pattern then has start of

coil 2 (bottom layer) going to start of coil 3 (also bottom layer).

When the copper tube with the coils is placed around the rotor, the

distance from any magnet to any coil must be identical. If it measures

different, acrylic holding shapes can be bolted to the aluminum base,

protruding upward, and thus push the copper tube in the direction needed

to maintain the spacing as stated.

23) Wires to load.

24) Wires to start switch.

25) Rotational direction which is clock-wise when viewing from top down.

26) Acrylic dome for protection against elements.

27)

Coating of clear acrylic to solidify rotor. Do not use standard motor

varnish. Pre-heat the rotor and then dip it into heated liquid acrylic.

After removal from dip tank, hand rotate until the acrylic hardens, then

balance rotor. For balancing procedure, either add brass weights or

remove brass as needed by drilling small holes into rotor on its heavy

side.

28) Insulation tubing on all connections.

29) Shaft for start purposes and speed testing (if desired).

This concludes the parts list for the Mini-Romag.

This simple

free energy generator

demonstrates profound concepts and has a surprising number of

applications. Remember, it must have a load to work, something that

attracts magnetic energy. Build this unit and explore new possibilities

of creating “free energy” yourself!

James

Tuchel, a 19 year-old from Grand Bahamas, has developed his own water

powered hybrid car in less than 2 months using local suppliers and

materials.

James

Tuchel, a 19 year-old from Grand Bahamas, has developed his own water

powered hybrid car in less than 2 months using local suppliers and

materials.

Of

all the subjects in the alternative energy world, I liked the “Free

Energy” part best. It’s not that I’m an absurd non-science,

self-proclaimed geek, but I like to give a chance to new ideas of

changing the world, and I still strongly believe we’re not being told

everything.

Of

all the subjects in the alternative energy world, I liked the “Free

Energy” part best. It’s not that I’m an absurd non-science,

self-proclaimed geek, but I like to give a chance to new ideas of

changing the world, and I still strongly believe we’re not being told

everything.

The Mini Romag free energy generator

from Magnetic Energy uses the principle of moving magnetic flow named

“the magnetic current” for generating electrical power. According to

Magnetic Energy this generator is able to produce 3.5 volts, 7A DC (

about 24 Watts ) of free electricity while its generate sufficient power

to sustain itself…

The Mini Romag free energy generator

from Magnetic Energy uses the principle of moving magnetic flow named

“the magnetic current” for generating electrical power. According to

Magnetic Energy this generator is able to produce 3.5 volts, 7A DC (

about 24 Watts ) of free electricity while its generate sufficient power

to sustain itself…